Product Category

- Suspended Platform

- -Steel power Painting Suspended Platform

- -Aluminum Alloy Suspended Platform

- - Hot Galvanized Suspended Platform

- -ZLP630 Suspended Platfrom

- -ZLP800 Suspended platform

- Brick Making Machine

- Self-Propelled Scissors Lift

- Suspended Platform Parts

- Construction Elevator

- Electric Scaffolding

- Mini Crane

- Crusher

- -PE Series Jaw Crusher

- -CS Series Cone Crusher

- -PY Series Cone Crusher

- -PF Series lmpact Crusher

- -PEV Series Jaw Crusher

- -VSl Series Vertical Shaft Impact Crusher

- -XS Series Sand Washer

- -ZSW Vibration Feeder

- -FG Series Spiral Sand Washer

- -YK Series Circular Vibrating Screen

- -CZG Series Vibration Feeder

- -BS Series Belt Conveyor

Product Detail

QT8-15 hydraulic concrete block making machine

Specification:

Main Technical Specifications | ||

Standard | JC/T920-2003 | |

Vibration Frequency | 4500 r/min | |

Vibration Pressure | 75KN | |

Motor Specification | Vibration Motor(kw) | 7.5x2 |

Hydraulic Motor(kw) | 18.5 | |

Concrete Feeder Motor(kw) | 4 | |

Belt Conveyor (kw) | 2.2 | |

Stacker Motor | 1.5x2 | |

Wet Block Conveyor Motor | 1.5 | |

Production/mould | Hollow block(390X190X190mm) 8Pics/mould | |

Hollow block(240X115X90mm) 21Pics/mould | ||

Solid brick (240X115X53 mm) 32 Pics/mould | ||

Paver brick(200X100X60mm) 24Pics/mould | ||

Cycle Time | 16-25seconds | |

Production/day(8hours) | Hollow block (390×190×190 mm) 9300-11000 Pics | |

Hollow block (240×115×90 mm) 24000-26000 Pics | ||

Solid brick (240×115×53mm) 60000-70000Pics | ||

Paver brick (200×100×60 mm) 27000-30000Pics | ||

Motor Power | 44.2Kw | |

Water Consumption | 5-10T | |

Number of workers | 7-10worker | |

Space of Ground | 5200 square meters | |

Gross Weight | 10.2T | |

Machine Dimension | 5400×1960×3050mm | |

Main materials | Cement,crushed stone dust,gravel,sand,coal fly ash,iron/aluminium dust,crushed cinder and some industrial wastes | |

Products of machine | Hollow blocks,Solid bricks,Pavers,Kurbstones,Slope blocks,slabs, interlock bricks and so on. | |

Manufactoring process:

1,Raw material:cement,sand,crushed stone dust,gravel,coal fly ash and so on.

2,Material through forklift to batching machine,batching machine can weigh and sifting the material.

3,After weighing,the material drop to hopper to mixing machine,mixing machine mix the material to concrete.

4,Concrete through concrete feeder to hopper.

5,Hopper drop the concrete on mould.

6,After hydraulic pressure and vibrating force,get wet block from mould.

7,Mould put the wet blocks on pallet.

8,Move pallet to yard for water curing.

9,After 3-5days water curing,the blocks can be sold,the best is after 7days water curing.

Working Live-action:

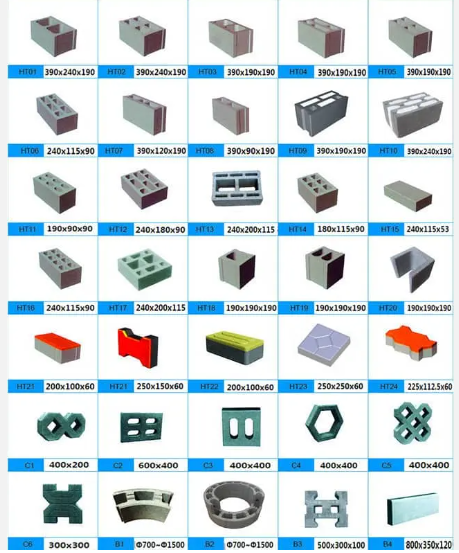

Block samples:

Different models:

Hongming Customers:

Hongming Factory

Guarantee and after-sale service:

1,Guarantee time is one year.

2,Engineer is available to oversea service

3,24h technical surport by e-mail and phone.

Whatsapp:+86 183 66469624 /