Product Category

- Suspended Platform

- -Steel power Painting Suspended Platform

- -Aluminum Alloy Suspended Platform

- - Hot Galvanized Suspended Platform

- -ZLP630 Suspended Platfrom

- -ZLP800 Suspended platform

- Brick Making Machine

- Self-Propelled Scissors Lift

- Suspended Platform Parts

- Construction Elevator

- Electric Scaffolding

- Mini Crane

- Crusher

- -PE Series Jaw Crusher

- -CS Series Cone Crusher

- -PY Series Cone Crusher

- -PF Series lmpact Crusher

- -PEV Series Jaw Crusher

- -VSl Series Vertical Shaft Impact Crusher

- -XS Series Sand Washer

- -ZSW Vibration Feeder

- -FG Series Spiral Sand Washer

- -YK Series Circular Vibrating Screen

- -CZG Series Vibration Feeder

- -BS Series Belt Conveyor

Product Detail

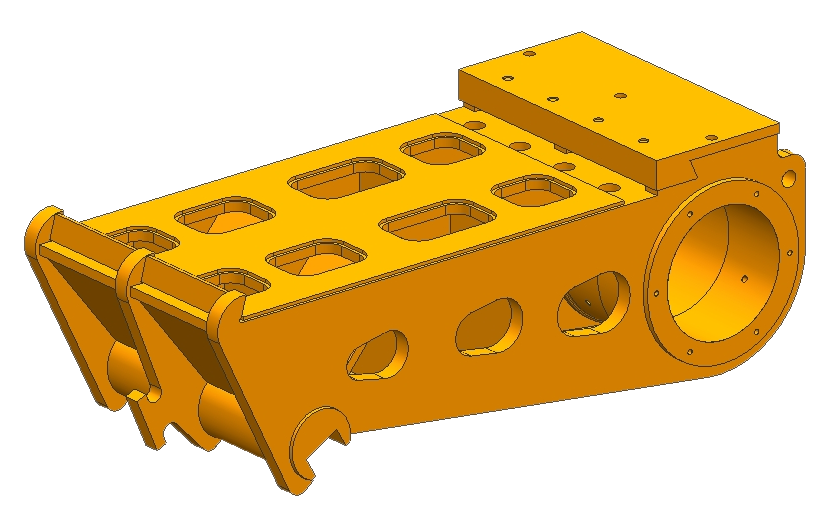

PE jaw crusher

Using the design principle of traditional compound pendulum jaw crusher, the mechanism has the advantages of simple structure, easy operation and maintenance, stable performance, and is suitable for various hard and brittle materials. Since the end of the 19th century, the machine is widely used in ore crushing, building aggregate processing and other industries, PE series is mainly used for various ore and rock crushing operation, compressive strength does not exceed 3MPa.

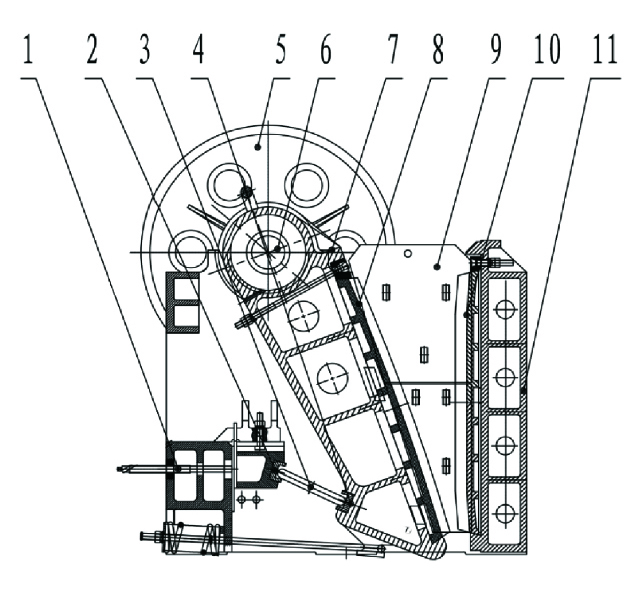

Main component name:

1. Top wire 2. Adjusting seat 3. Elbow pad 4. Elbow pad 5. Flywheel 6. Eccentric shaft 7. Moving jaw head 8. Moving jaw plate 9. Side guard plate 10. Fixed jaw plate 11. Rack

For the jaw crusher operating conditions are usually harsh, parts wear fast and other characteristics, we are very elegant in the selection of core materials, in accordance with the more advanced models in the world, the use of currently recognized high quality high manganese steel. The contact surface of the casting is machined to ensure the size of the core assembly. The scheme greatly extends the service life of the wearing parts and effectively avoids the excessive maintenance of downtime and the occupation of production time.

The jaw crusher moves with the rotation of the eccentric shaft, and the trajectory becomes flatter and flatter with the downward movement of the ellipse. This complex swinging mode makes the crushing chamber have a better crushing and friction effect on the material, and the crushing particle size is more uniform.

Specification Parameter

| Model | jaw opening size (mm) | feed size (mm) | Discharge size (mm) | main shaft rotate spee d (r/min) | Processing ability (t/h) | power (kw) |

| PE400×600 | 400×600 | ≤340 | 40-90 | 270 | 15-40 | 30 |

| PE500×750 | 500×750 | ≤480 | 50-110 | 270 | 20-80 | 55 |

| PE600×900 | 600×900 | ≤510 | 65-130 | 260 | 50-150 | 75 |

| PE750×1060 | 750×1060 | ≤630 | 80-140 | 250 | 100-180 | 110 |

| PE900×1200 | 900×1200 | ≤760 | 100-230 | 220 | 180-280 | 132 |

| PE1200×1500 | 1200×1500 | ≤1000 | 150-350 | 180 | 300-800 | 200 |

| PE1500×1800 | 1500×1800 | ≤1200 | 220-350 | 180 | 500-1000 | 355 |

| PEX250×1200 | 250×1200 | ≤210 | 25-60 | 345 | 15-50 | 37 |

| PEX300×1300 | 300×1300 | ≤250 | 25-90 | 310 | 20-70 | 75 |

| PEX500×1500 | 500×1500 | ≤350 | 30-150 | 250 | 50-150 | 90 |

Clients'Feedback