Product Category

- Suspended Platform

- -Steel power Painting Suspended Platform

- -Aluminum Alloy Suspended Platform

- - Hot Galvanized Suspended Platform

- -ZLP630 Suspended Platfrom

- -ZLP800 Suspended platform

- Brick Making Machine

- Self-Propelled Scissors Lift

- Suspended Platform Parts

- Construction Elevator

- Electric Scaffolding

- Mini Crane

- Crusher

- -PE Series Jaw Crusher

- -CS Series Cone Crusher

- -PY Series Cone Crusher

- -PF Series lmpact Crusher

- -PEV Series Jaw Crusher

- -VSl Series Vertical Shaft Impact Crusher

- -XS Series Sand Washer

- -ZSW Vibration Feeder

- -FG Series Spiral Sand Washer

- -YK Series Circular Vibrating Screen

- -CZG Series Vibration Feeder

- -BS Series Belt Conveyor

Product Detail

PEV series European version jaw crusher

1. Sturdy structure

The rack can be divided into two types: welded and assembled for small and medium-sized specifications, and assembled for large specifications.

The welding method adopts a large arc transition fillet and low stress zone welding method, greatly reducing stress concentration and ensuring equal strength of the frame in all directions. It has characteristics such as impact resistance, uniform stress distribution, and low failure rate.

The assembly type adopts advanced modular and welding free frame structure design, with high fatigue strength and reliability. At the same time, the whole machine assembly design makes transportation and installation more convenient, especially suitable for installation in narrow and difficult transportation places such as underground mines and high-altitude mines.

Our company has introduced advanced international crushing technology and research achievements, combined with years of experience in designing and manufacturing jaw crushers, and successfully developed a new generation of products using finite element analysis method.

2. Superior cavity design

Symmetric "V" - shaped cavity design, with large elbow angle, large stroke, and reasonable rotation speed, makes the feed particle size larger, the output higher, and the particle size more uniform, reducing jaw wear.

3. The heavy-duty jaw assembly is durable and long-lasting

The heavy-duty moving jaw assembly adopts a forged heavy-duty eccentric shaft, high-quality heavy-duty rolling bearings, and a finite element software optimized moving jaw body, ensuring high impact resistance and stability of the moving jaw assembly; The labyrinth seal and centralized lubrication system ensure that the bearing grease is not contaminated and lubrication is more convenient, making it run longer and more stable.

4. Design of movable jaw guard board

A heavy-duty protective plate is installed above the movable jaw to avoid material impact and effectively protect the movable jaw body and its internal bearings from damage.

5. Integrated bearing seat

The overall cast steel bearing seat structure ensures complete compatibility with the frame, avoiding unnecessary radial loads on the bearing caused by the combined bearing seat during the tightening process, making the bearing operation smoother.

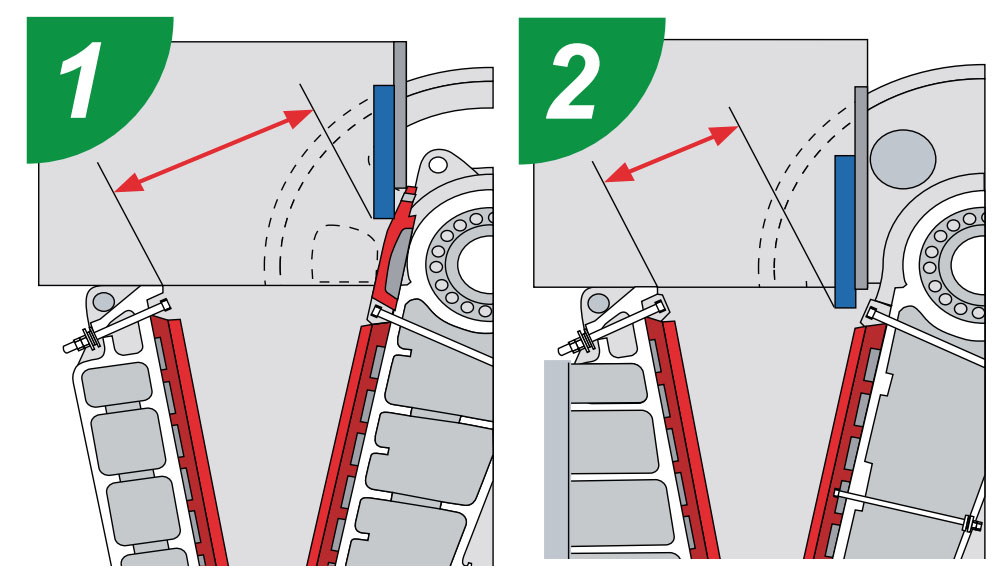

6. Convenient and fast granularity adjustment

The PEV jaw crusher adopts a mechanical or hydraulic discharge port adjustment device, the mechanical type adopts a double wedge block adjustment method corresponding to the gasket adjustment, and the hydraulic type adopts a straight top structure, making the operation simpler, safer, and faster, saving downtime.

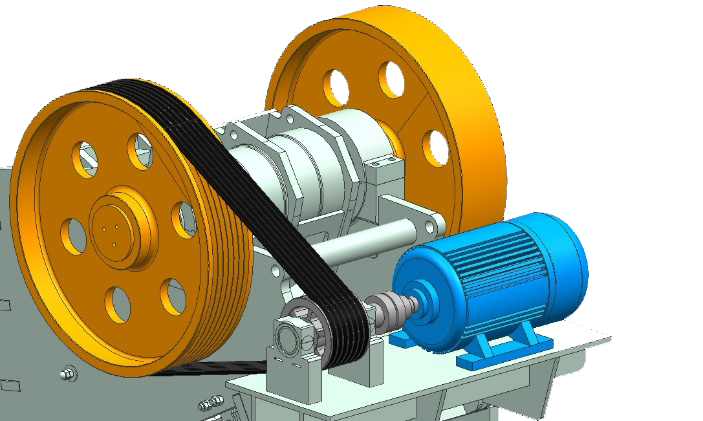

7. Integrated motor installation

The integrated installation method of the motor base and crusher frame not only saves the installation space of the jaw crusher and reduces the length of the V-belt, but also achieves the adjustment of the V-belt tension due to the synchronous movement of the frame, motor base, and motor, and the adjustable motor base, resulting in a longer service life of the V-belt.

8. Shock absorption installation design

The crusher is fixed with a dedicated rubber shock-absorbing device, which effectively absorbs the peak vibration of the equipment and allows for vertical and longitudinal displacement of the crusher, thereby reducing the impact on the foundation.

Main Technical Parameter

| Model | PEV600×900 | PEV700×1060 | PEV900×1200 | |

| Feeding Opening Width (mm) | 900 | 1060 | 1200 | |

| Feeding Opening Deepth(mm) | 600 | 700 | 900 | |

| Power (kw) | 90 | 132 | 160 | |

| Feed Size (mm) | Out Size (mm) | Capacity(t/h) | ||

| 0-90 | 60 | 120-155 | ||

| 0-105 | 70 | 140-180 | 155-200 | |

| 0-120 | 80 | 160-210 | 175-230 | |

| 0-135 | 90 | 180-235 | 200-260 | |

| 0-150 | 100 | 200-260 | 220-290 | 290-380 |

| 0-185 | 125 | 250-325 | 280-365 | 350-455 |

| 0-225 | 150 | 300-390 | 335-435 | 410-535 |

| 0-260 | 175 | 350-455 | 390-510 | 470-610 |

| 0-300 | 200 | 445-580 | 530-690 | |

| 0-340 | 225 | 590-770 | ||

| 0-375 | 250 | 650-845 | ||

Load Pics

Load Pics