Product Category

- Suspended Platform

- -Steel power Painting Suspended Platform

- -Aluminum Alloy Suspended Platform

- - Hot Galvanized Suspended Platform

- -ZLP630 Suspended Platfrom

- -ZLP800 Suspended platform

- Brick Making Machine

- Self-Propelled Scissors Lift

- Suspended Platform Parts

- Construction Elevator

- Electric Scaffolding

- Mini Crane

- Crusher

- -PE Series Jaw Crusher

- -CS Series Cone Crusher

- -PY Series Cone Crusher

- -PF Series lmpact Crusher

- -PEV Series Jaw Crusher

- -VSl Series Vertical Shaft Impact Crusher

- -XS Series Sand Washer

- -ZSW Vibration Feeder

- -FG Series Spiral Sand Washer

- -YK Series Circular Vibrating Screen

- -CZG Series Vibration Feeder

- -BS Series Belt Conveyor

Product Detail

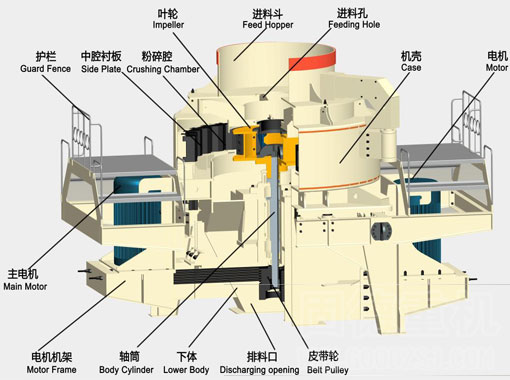

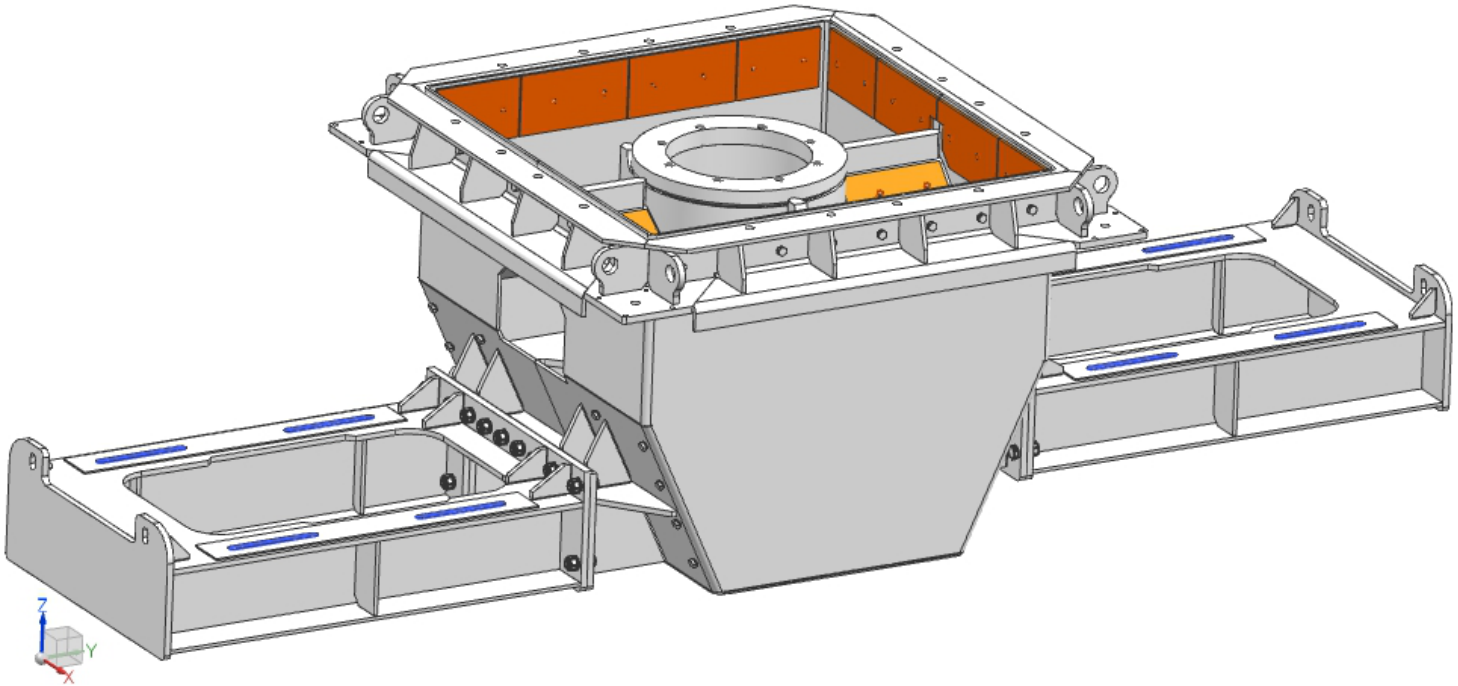

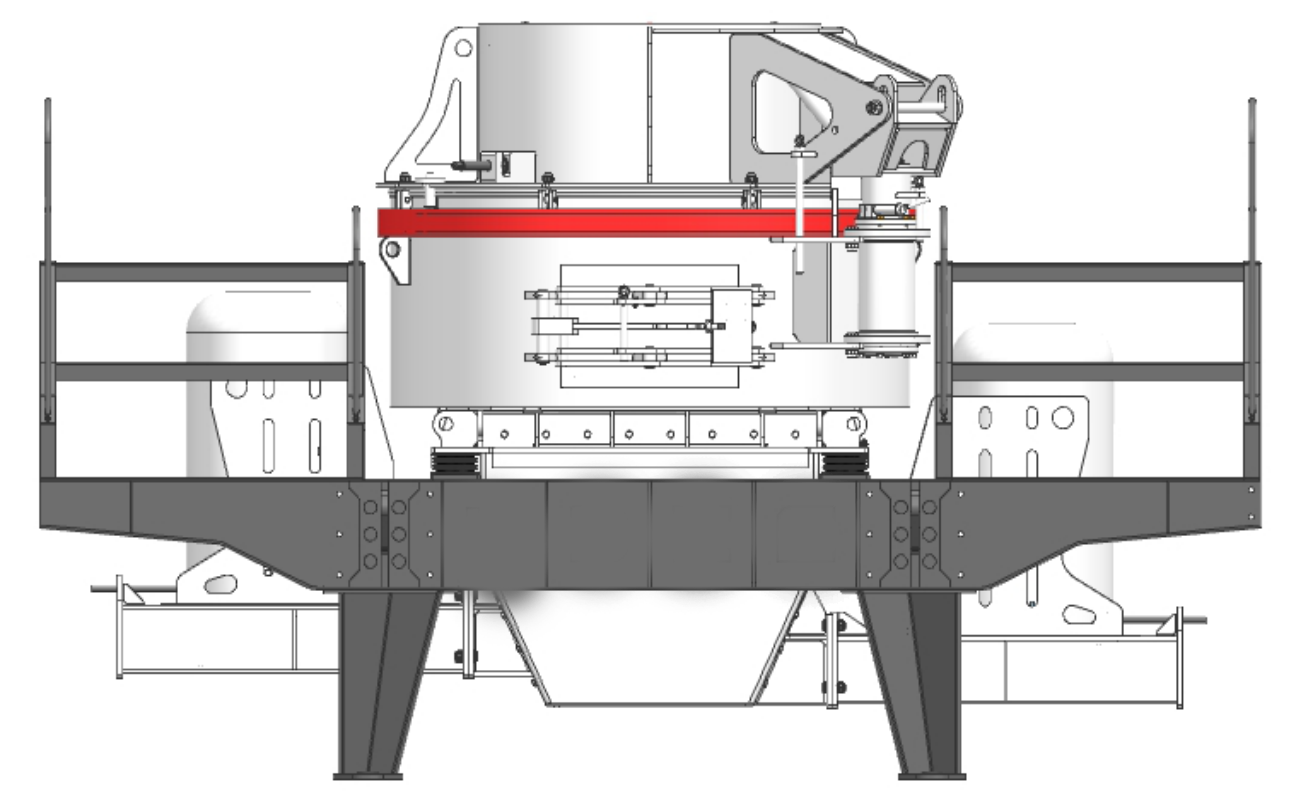

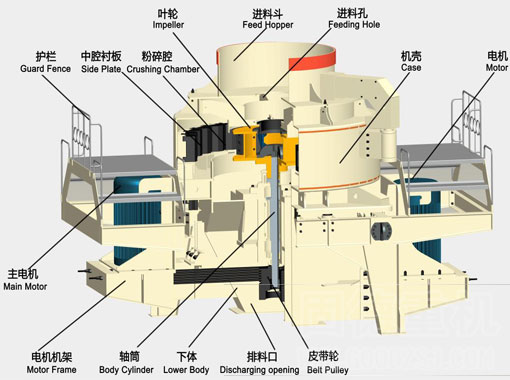

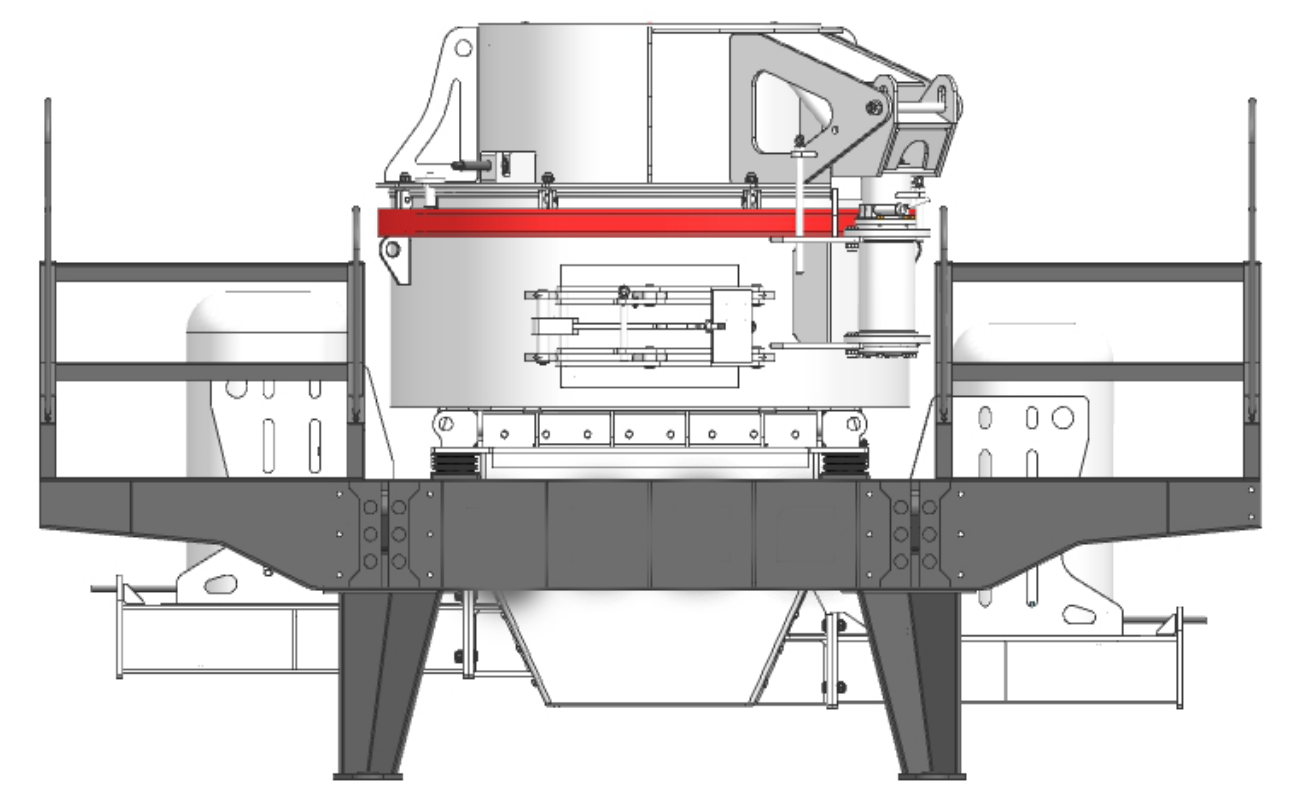

VSl Series Vertical Shaft Impact Crusher

1.VSl series vertical shaft impact crusher is thenew generation of sand making machine, with thecharacteristics of optimized structure, stable performance,easy maintenance, low running cost etc. lt is widely usedto crush material with a hardness below grade 9(HV<9)especially for sand making, mining ore crushing etc.

2.VSI vertical axis impact breaking is applied in the medium and fine crushing fields of various high and extra hard materials such as ores, cement, refractory materials, bauxite clinker, diamond sand, glass raw materials, etc. It can also be widely used in fine crushing operations in industries such as hydropower, highways, construction, cement, and metal mines.

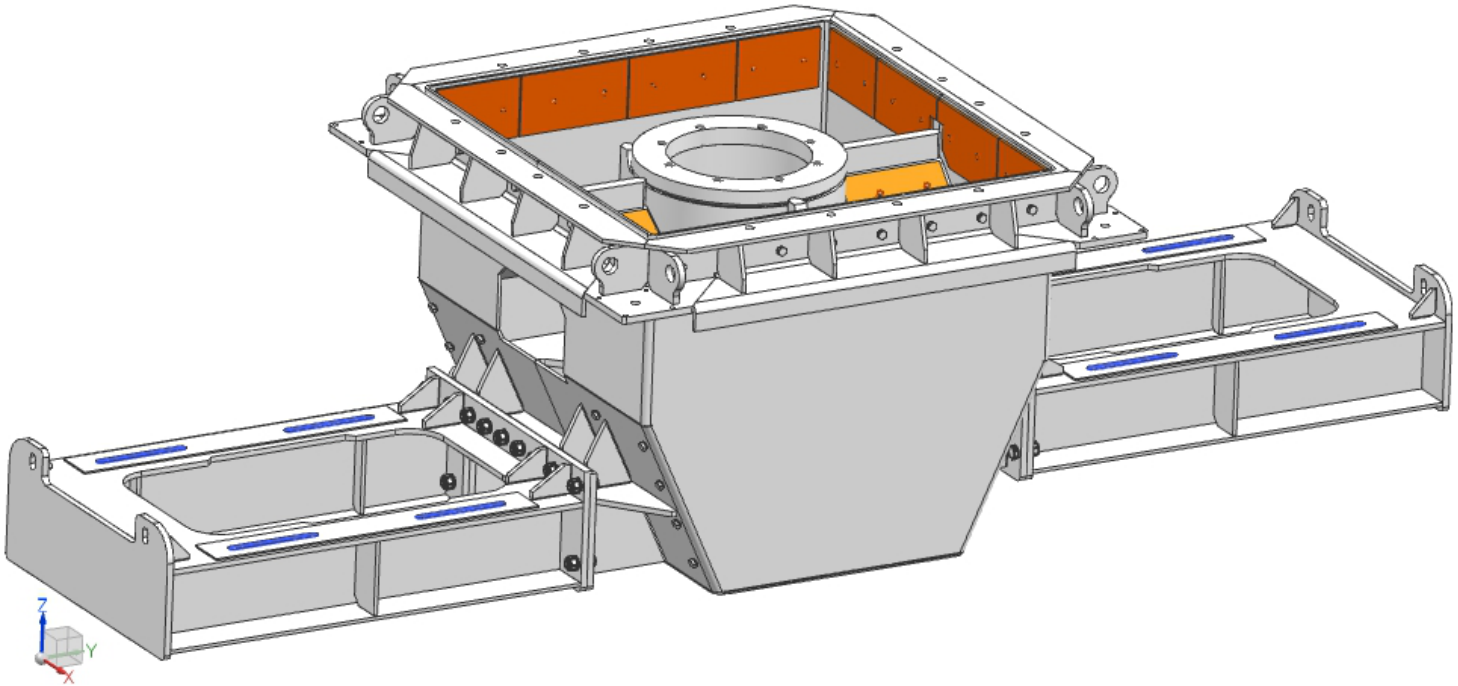

Full center feeding: The material falls into the feeding hopper of the sand making machine, enters the high-speed rotating throwing wheel through the center feeding hole, and is rapidly accelerated inside the throwing wheel, with an acceleration of tens of times the gravitational acceleration. It is then thrown out of the throwing wheel at high speed, first colliding with another part of the material that falls freely after rebounding, and then colliding with the material lining layer (stone striking stone) or counterattack block (stone striking iron). It is rebounded and obliquely impacted upwards to the top of the vortex chamber, changing its direction of movement, deflecting downwards, and then colliding with the material emitted from the impeller channel to form a continuous material curtain. In this way, a piece of material is subjected to two to multiple chances of impact, friction, and grinding crushing in the vortex crushing chamber. The crushed material is discharged from the lower discharge port .

Central feeding accompanied by circular waterfall feeding

The material falls into the feeding hopper of the sand making machine, falls through the annular hole, and is divided into two streams

by the dividing plate. One stream enters the high-speed rotating throwing wheel through the dividing plate, and the other stream

falls from around the dividing plate. The material entering the impeller is rapidly accelerated within the impeller, with an acceleration

of several tens of times that of gravity. It is then thrown out of the impeller at high speed and first collides with another part of the

material that falls freely around the distributor to break it. Then, it collides with the vortex lining layer in the vortex chamber, rebounds

by the material lining layer, and obliquely impacts the top of the vortex chamber, changing its direction of movement, deflecting

downwards, and then collides with the material emitted from the impeller channel to form a continuous material curtain. In this way,

a piece of material is subjected to two to multiple chances of impact, friction, and grinding crushing in the vortex crushing chamber.

The crushed material is discharged from the lower discharge port.

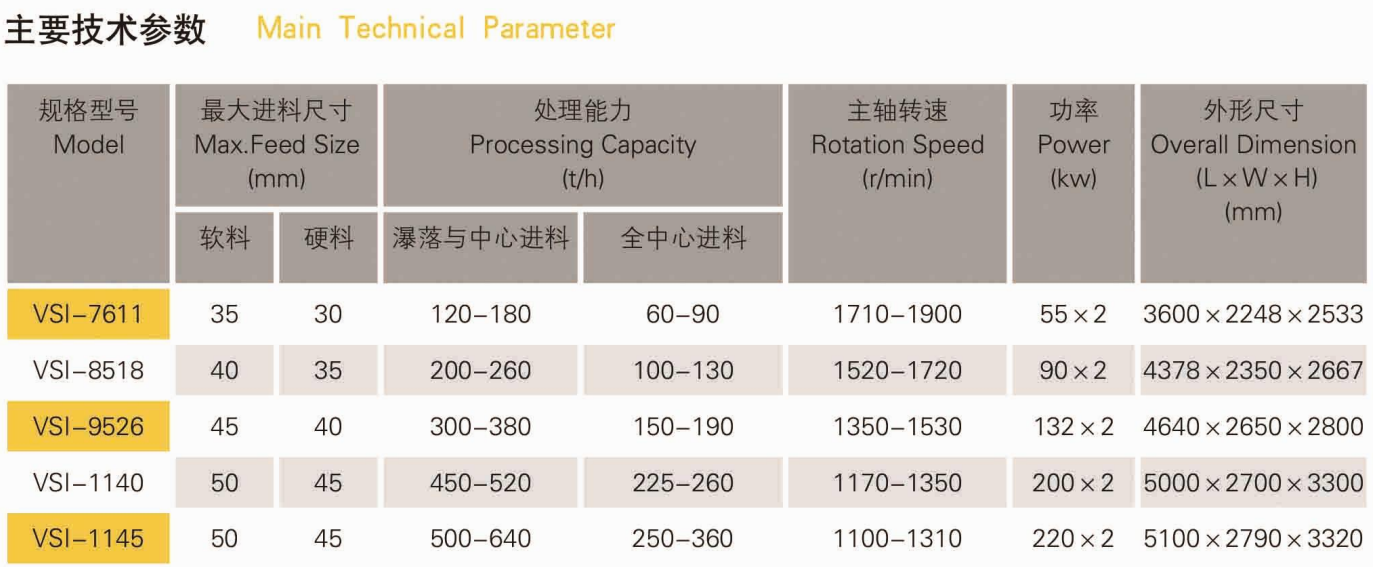

Main Technical Parameter

Clients' Feedback