Product Category

- Suspended Platform

- -Steel power Painting Suspended Platform

- -Aluminum Alloy Suspended Platform

- - Hot Galvanized Suspended Platform

- -ZLP630 Suspended Platfrom

- -ZLP800 Suspended platform

- Brick Making Machine

- Self-Propelled Scissors Lift

- Suspended Platform Parts

- Construction Elevator

- Electric Scaffolding

- Mini Crane

- Crusher

- -PE Series Jaw Crusher

- -CS Series Cone Crusher

- -PY Series Cone Crusher

- -PF Series lmpact Crusher

- -PEV Series Jaw Crusher

- -VSl Series Vertical Shaft Impact Crusher

- -XS Series Sand Washer

- -ZSW Vibration Feeder

- -FG Series Spiral Sand Washer

- -YK Series Circular Vibrating Screen

- -CZG Series Vibration Feeder

- -BS Series Belt Conveyor

Product Detail

Product Description

1. Large processing capacity and low production cost.

2. High cleaning efficiency with multiple functions.

3. Simple structure with low failure rate.

4. A good structural layout and effective sealing design enable the machine to withstand long-term maintenance and durability; Low water consumption, low working noise, and compliance with national environmental standards.

Processing materials: river pebbles, granite, basalt, quartz, iron ore, diabase, limestone, coal gangue, etc.

The XS series sand washing machine, commonly known as the wheel bucket sand washing machine, is an efficient sand washing equipment developed and produced by Federal Heavy Industry using advanced domestic and foreign technology, combined with the actual situation of the domestic sand and gravel industry, for use with sand making machines.

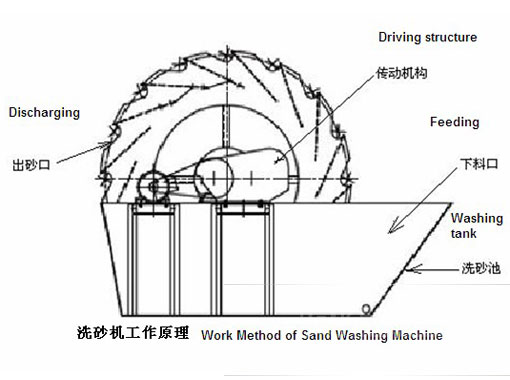

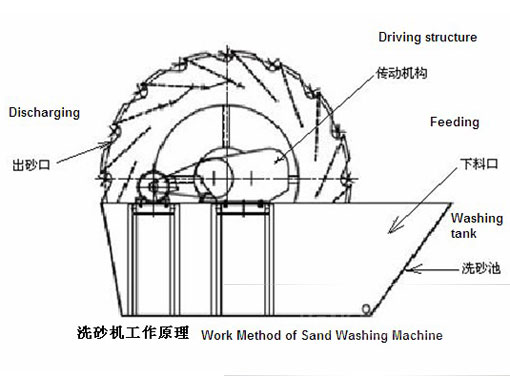

Working Principle

When the sand washing machine is in operation, the motor drives the impeller to slowly rotate through a V-belt, reducer, and gear reduction. The sand and gravel enter the washing tank through a feeding groove, and under the drive of the impeller, they roll and grind each other to remove impurities covering the surface of the sand and gravel. At the same time, the water vapor layer that covers the sand particles is destroyed to facilitate dehydration; At the same time, add water to form a strong water flow, timely remove impurities and small foreign objects, and discharge them from the overflow outlet washing tank to complete the cleaning function. The clean sand and gravel are taken away by the blades, and after being cleaned, the sand and gravel are poured into the discharge groove from the rotating impeller to complete the cleaning function of the sand and gravel.

规格参数 Technical Parameter

| Model | Wheel Bucket Dia(mm) | Feed grain size(mm) | capacity (t/h) | power(kw) | overall dimension (mm) |

| XS2610 | 2600 | ≤10 | 40-60 | 4 | 3220*2125*2670 |

| XS3010 | 3000 | ≤10 | 50-70 | 4 | 3670*1970*3140 |

| XS3015 | 3000 | ≤10 | 80-110 | 5 | 3670*2670*3140 |

| XS3020 | 3000 | ≤10 | 120-200 | 7.5-11 | 3670*3300*3200 |

| XS4520 | 4500 | ≤10 | 180-250 | 11-15 | 5170*3300*4700 |

| XS6020 | 6000 | ≤10 | 220-300 | 18.5 | 6700*3700*6400 |