Product Category

- Suspended Platform

- -Steel power Painting Suspended Platform

- -Aluminum Alloy Suspended Platform

- - Hot Galvanized Suspended Platform

- -ZLP630 Suspended Platfrom

- -ZLP800 Suspended platform

- Brick Making Machine

- Self-Propelled Scissors Lift

- Suspended Platform Parts

- Construction Elevator

- Electric Scaffolding

- Mini Crane

- Crusher

- -PE Series Jaw Crusher

- -CS Series Cone Crusher

- -PY Series Cone Crusher

- -PF Series lmpact Crusher

- -PEV Series Jaw Crusher

- -VSl Series Vertical Shaft Impact Crusher

- -XS Series Sand Washer

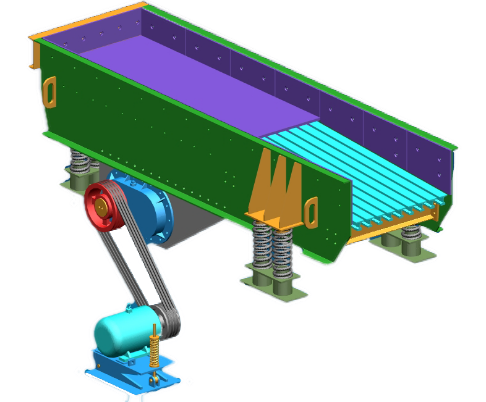

- -ZSW Vibration Feeder

- -FG Series Spiral Sand Washer

- -YK Series Circular Vibrating Screen

- -CZG Series Vibration Feeder

- -BS Series Belt Conveyor

Product Detail

Product Description

Product features and technological advantages

1. Equipped with pre screening function, widely suitable for various industries;

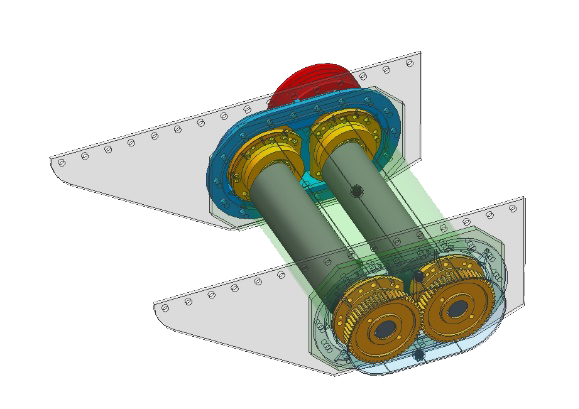

2. Double eccentric shaft exciter, more powerful than general exciters;

3. Inheriting classic design with guaranteed performance;

4. The optimized simple structure makes maintenance operations more convenient;

5. Special grating design can prevent material blockage;

6. The gap between the bars is adjustable.

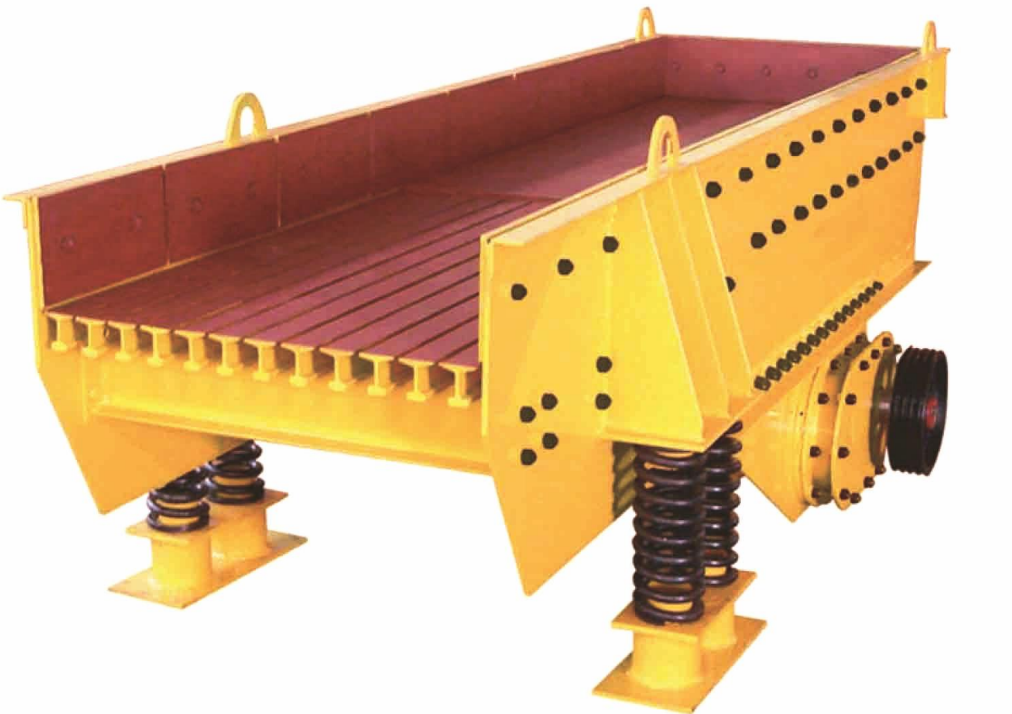

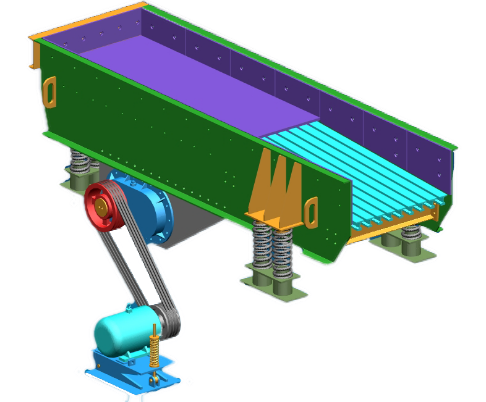

The ZSW series vibrating feeder adopts the structural feature of a double eccentric shaft exciter, ensuring that the equipment can withstand the impact of large materials falling and has a large feeding capacity. In the production process, it can evenly, regularly, and continuously deliver and granular materials from the storage bin to the receiving device, thereby preventing the receiving device from crashing due to uneven feeding and prolonging the equipment's service life. The feeder can be divided into a steel plate structure and a grate structure. The feeder of the steel plate structure is mostly used in the sand and gravel production line to evenly send all the materials into the crushing equipment; the feeder of the grate structure can perform coarse screening on the materials, making the system more economically and reasonably configured. It has become an indispensable equipment in crushing and screening. Therefore, this machine is widely used in the crushing and screening combined equipment in industries such as metallurgy, coal mining, mineral processing, building materials, chemical industry, and abrasives.

Working Principle

The ZSW series vibrating feeder is composed of the feeding chute body, exciter, spring support, transmission device, etc. The vibration source of the chute body for vibrating feeding is the exciter. The exciter is composed of two eccentric shafts (driving and driven) and a gear pair. The motor drives the driving shaft through a V-belt, and then the gear on the driving shaft engages to rotate the driven shaft. The driving and driven shafts rotate in opposite directions simultaneously, causing the chute body to vibrate, enabling the continuous flow of materials and achieving the purpose of conveying materials.

Technical Parameter

| Model | Feed Size(mm) | Processing Capacity (t/h) | Groove Face Inclination(°) | Power (kw) | Double amplitude (mm) |

| ZSW380-96 | ≤500 | 70-140 | 0 | 11 | 9 |

| ZSW490-110 | ≤600 | 120-250 | 0 | 18.5 | 10 |

| ZSW590-120 | ≤700 | 180-350 | 0 | 22 | 10 |

| ZSW600-130 | ≤800 | 250-150 | 0 | 30 | 10 |

| ZSW600-150 | ≤1000 | 160-615 | 0 | 30/37 | 9 |

| ZSW600-180 | ≤1200 | 600-1000 | 0 | 37/45 | 9 |

Clients' Feedback

Loading Pics